tbmills

Gold Member

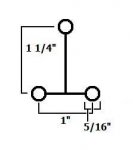

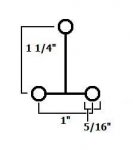

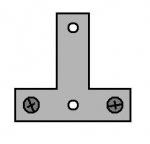

i have a 70s gretsch c.o.b. and the lightning throw is unreliable at best. i want to replace it with the dunnett gibraltar swivel strainer, but my snare has a strange triangular drilling pattern. how can i use a modern strainer without drilling?

here are some pics

here are some pics